Oilfield Tubular Inspection Services

Drill Pipe Inspection, Cleaning, Repair and Coating Services Available 24/7

Superior Inspection Services has extensive knowledge of API, DS1, and NS2 inspection criteria, and can adapt to all additional customer requirements. Services are performed both at our facilities and in the field 24 hours a day, 7 days a week. Our unique position includes capable trained/experienced personnel, facilities and equipment to perform all the services necessary to meet your needs.

Services Provided as Follows

- Two Full Length Ultrasonic Testing (FLUT) Units

- Ultrasonic Testing – UT thickness & shearwave

- 2 in Broussard, Louisiana

- 1 in Brazil

- Electro-Magnetic Inspection (EMI)

- Magnetic Particle Inspection

- Liquid Penetrant (PT)

- ID Hydro-blasting Services

- Multiple Dimensional Measurements

- Shot Blasting of OD and High Pressure Water ID Cleaning Systems

- 3 in Broussard

- 1 in Lubbock, Texas

- 1 in Brazil

- 1 in Aberdeen, UK

- Special End Area (SEA)

- Complete Maintenance and Storage

- Laser Tally Services

- O.D. Grinding

- Patented Inline Lathe Refacing System

- Hard Banding Services

- Global Services

- Exclusive Rust Grip™ OD Coating for oilfield-related tubulars

- Rust Grip™ OD Coating Plant in Broussard

- Range 2 and Range 3 friction welded and seamless CSG/TBG complete inspection capabilities

Full Length Ultrasonic Testing (FLUT)

Used to detect Transverse, Longitudinal and oblique flaws on the ID and the OD. Also, used to detect OD and ID Wall Loss with Ultrasonic wall thickness testing. Recommended for drill pipe when the measured wall thickness is greater than .5 inches.

Superior Inspection Services continues to invest in our people and the best quality equipment to provide integrated systems and services for our customers. With EMI capabilities and two Full Length Ultrasonic Testing (FLUT) units, Superior Inspection Services provides grinding and hard band services, patented in-line lathe refacing and also operates a coating facility to apply an exclusive Rustgrip™ OD coating to tubulars being used in the most challenging open water and completion applications.

Superior Inspection Services - Broussard, Louisiana

Shipping and Receiving Office, Maurice Road, Broussard, Louisiana

O.D. Shot Blast Unit

Utilized at all of our locations, the O.D. Shot Blast Unit removes rust and mud to thoroughly prepare the OD for inspection.

Hydroblast Cleaning Unit

Hydroblast Unit used to clean both O.D. and I.D.

Hydroblast Cleaning Unit: Close Up

Hydroblasting tube body full length OD and pin connections.

Hydroblast Operator

Hydroblast Operator controls rate of travel and pressure to ensure tubulars are thoroughly cleaned.

Cleaning

Range 3 capable. Multiple lances travel full length inside tubulars to ensure tube ID and box connections are thoroughly cleaned.

Cleaning Facility

One of Superior Inspection Services multiple cleaning facilities.

Pit Depth Measurement

Full length visual of tube body, O.D. gauging and verification of depth measurement being performed.

Connections Prep

Connections are prepared and dressed prior to visual and profile check.

Visual Inspection

Visual inspection being performed on pin connection.

Dimensional Inspection

Dimensional Inspection being performed on pin connections.

Enclosed Facility

One of Superior Inspection Services enclosed facilities where pipe is conveyed to multiple inspection lanes.

Full Length Ultrasonic Testing Units

Two Full Length Ultrasonic Testing units with two committed inspection lanes.

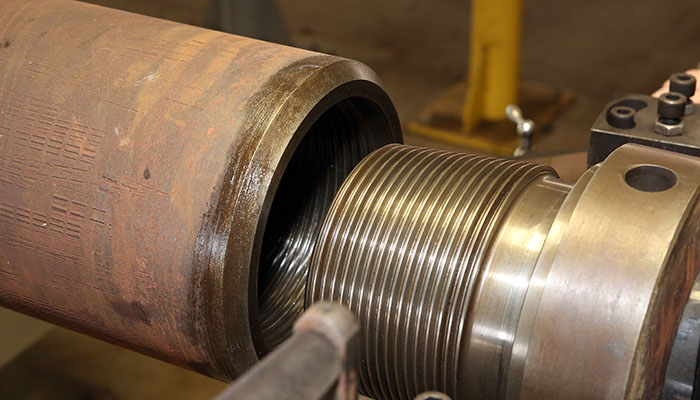

Mobile Inspection Units

Mobile Inspection Units allow us to perform inspection services at offsite locations.

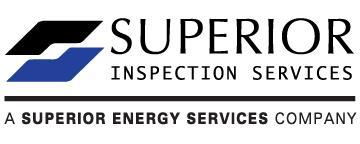

In-line Lathe Refacing

In-line Lathe Refacing with our patented refacing system.

Inline Refacing Prep

A box connection being prepared for refacing with our inline refacing unit.

Refaced and Re-beveled

A refaced and re-beveled pin connection completed with copper sulphate applied.

Digital Laser Tally

Digital Laser Tally being used to accurately measure and record lengths of tubulars prior to being shipped to location.

Hard Banding Unit

Hard Banding Unit used to apply hard band to tubular O.D.s to help reduce O.D. wear.

Hard Band

Hard Band applied to tool joint O.D.

Hard Banding Service

Certified applicator performing hard banding. Hard Banding service available at all Superior Inspection Services locations.

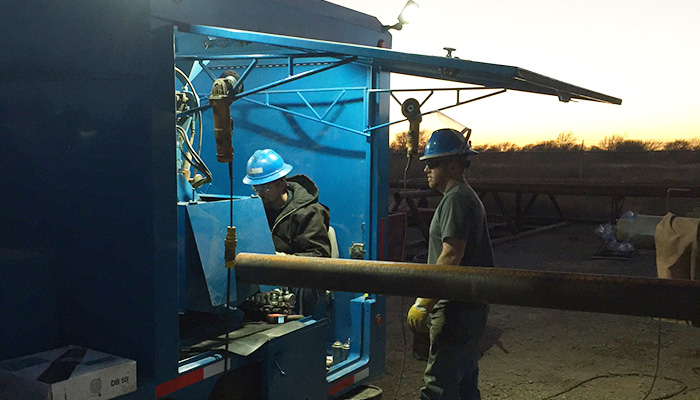

Rust Grip™ O.D. Coating

Rust Grip™ O.D. coating being applied to a tube body and tool joints to assist in mitigating corrosion and O.D. Pitting.

RustGrip™ O.D. Coating

RustGrip™ O.D. coating curing prior to being stenciled, moved and shipped to location offshore Gulf of Mexico.

Mill Varnish Application

Mill varnish applied to the O.D. of tubulars being staged for shipment to an international location.